Standard Laminated Glass is a type of safety glass that is made by sandwiching a layer of plastic (typically polyvinyl butyral or PVB) between two layers of glass. The plastic layer acts as a bonding agent, holding the glass together even if it is broken.

This type of glass is commonly used in a variety of applications, such as car windshields, skylights, and building windows. It offers a number of benefits over traditional glass, including:

Safety: If laminated glass is broken, the plastic layer holds the pieces together, preventing them from falling out and reducing the risk of injury.

Security: Laminated glass is more difficult to break through than traditional glass, making it a good choice for applications where security is a concern.

UV Protection: The plastic layer in laminated glass blocks out a significant amount of UV radiation, reducing the amount of fading that can occur in fabrics and other materials exposed to sunlight.

Sound Insulation: Laminated glass can also help to reduce the amount of noise that enters a building, making it a popular choice for use in homes, offices, and other commercial buildings.

Standard laminated glass is made by sandwiching PVB or other plastic layer between two layers of glass under high temperature and pressure. This process creates a strong, durable bond between the layers, and the glass can be cut, drilled, or shaped to fit any application.

It is also important to note that laminated glass can be made with different thicknesses of PVB or different types of glass, which can affect its properties such as acoustic insulation, UV protection, etc.

Standard Laminated Glass VS traditional glass

Article author: Admin

Hot Sale Product

-

Round Lighted LED Mirror with Anti-fog Dimmer C037

-

Round Wall Mounted Bathroom Lighted LED Mirror C039

-

Round Lighted LED Backlit Mirror with Clock C042

-

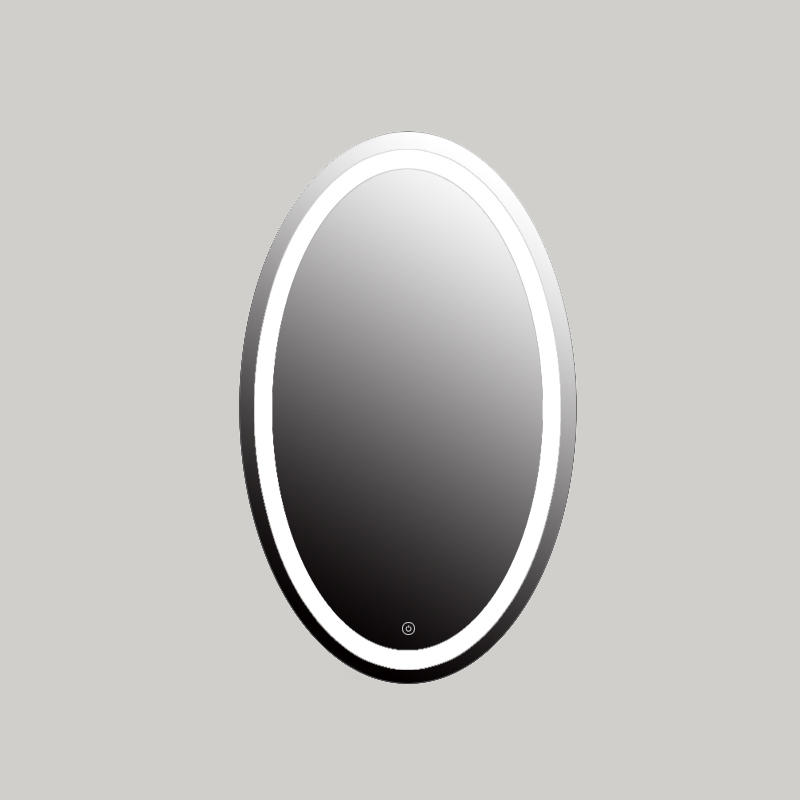

Oval Shape LED Lighted Wall Mirror ML-050

-

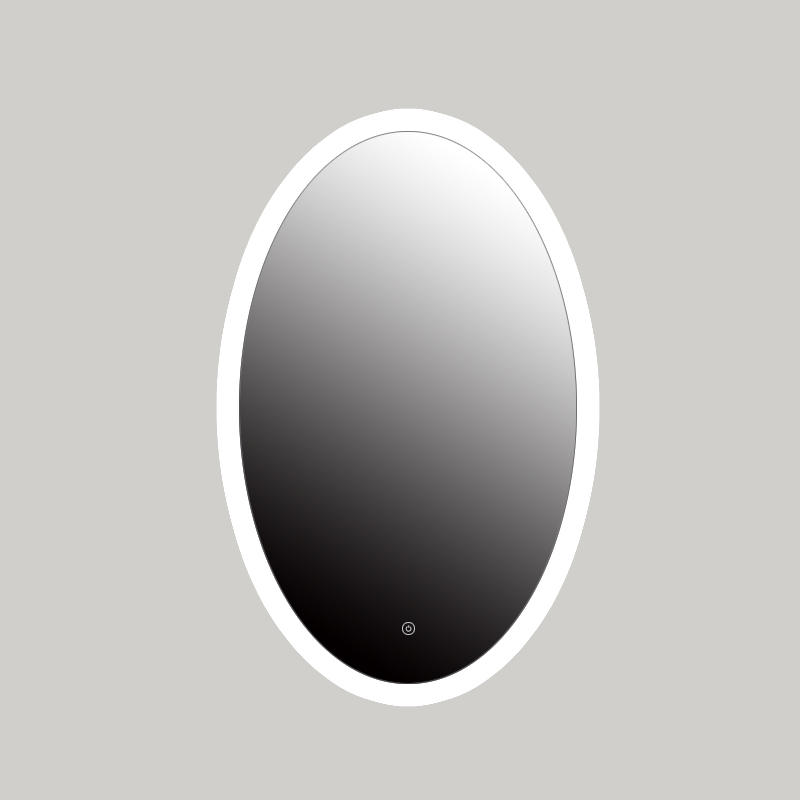

Oval Shape LED Illuminated Bathroom Mirror ML-051

-

Capsule Frameless Backlit Lighted Bathroom Mirror ML-071

-

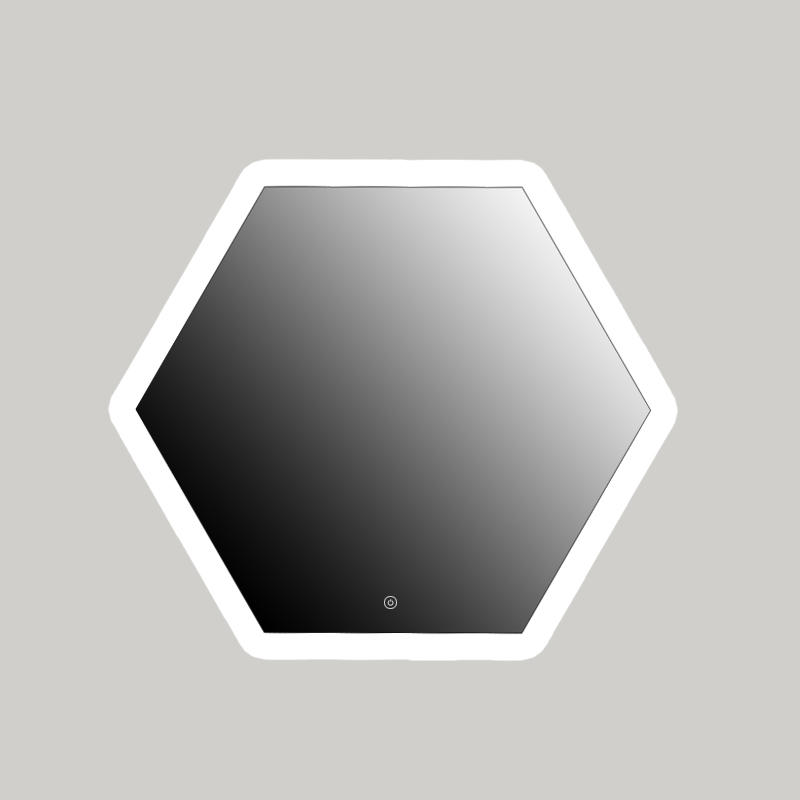

Hexagon Special Shape Decorative Bathroom LED Mirror ML-081

-

Round Metal Framed Touch Sensor LED Backlit Mirror MFL-01

-

Round Iron Aluminum Framed Anti-fog Bathroom Lighted Mirror with Color Temperature Changing MFL-02

-

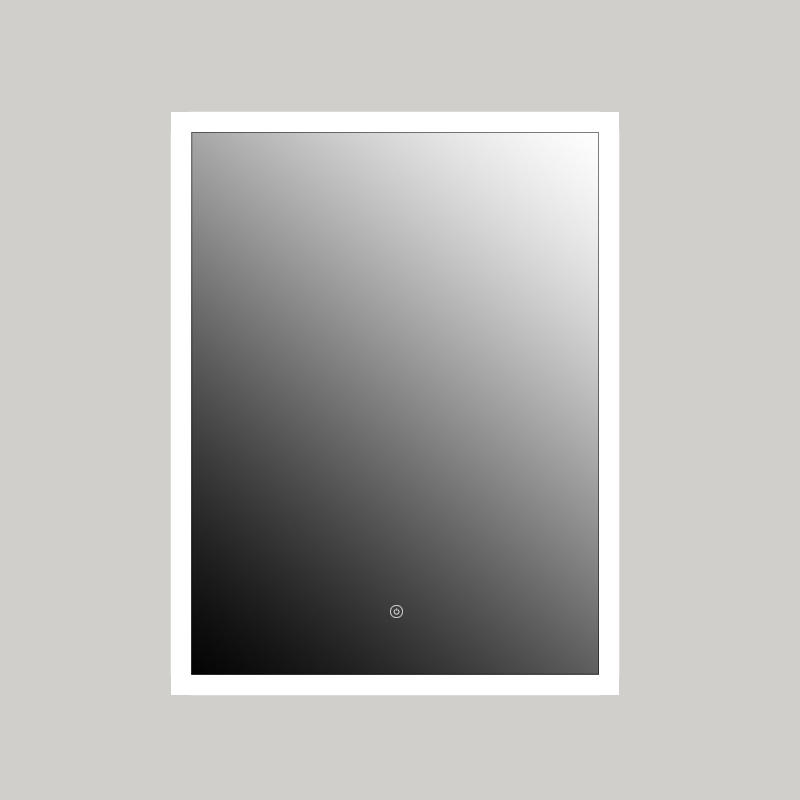

Rectangle Lighted Bathroom LED Mirror with Bluetooth C013

-

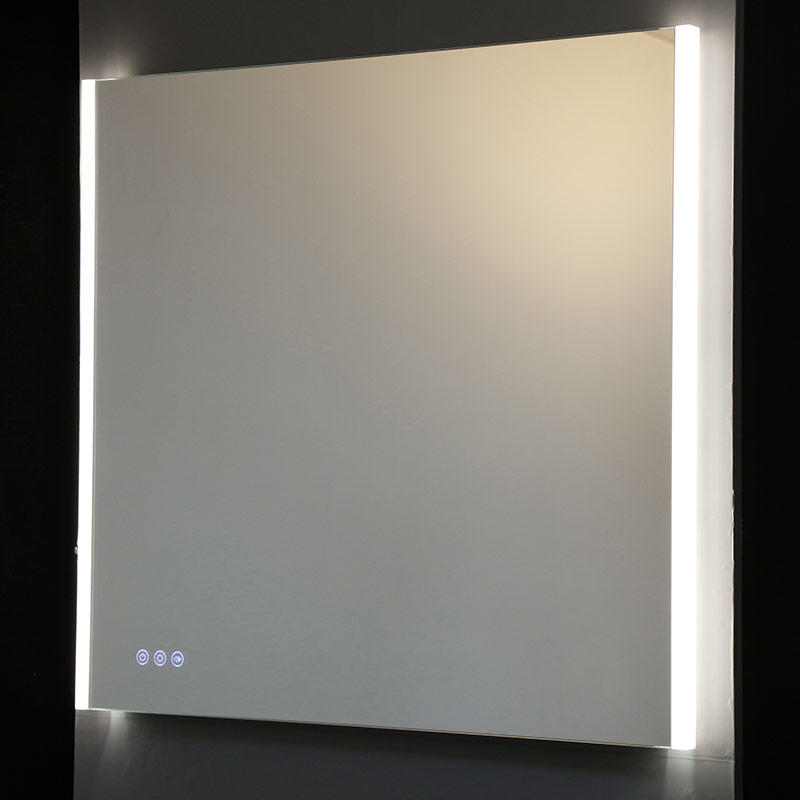

Rectangle LED backlit Mirror with Defogger C014

-

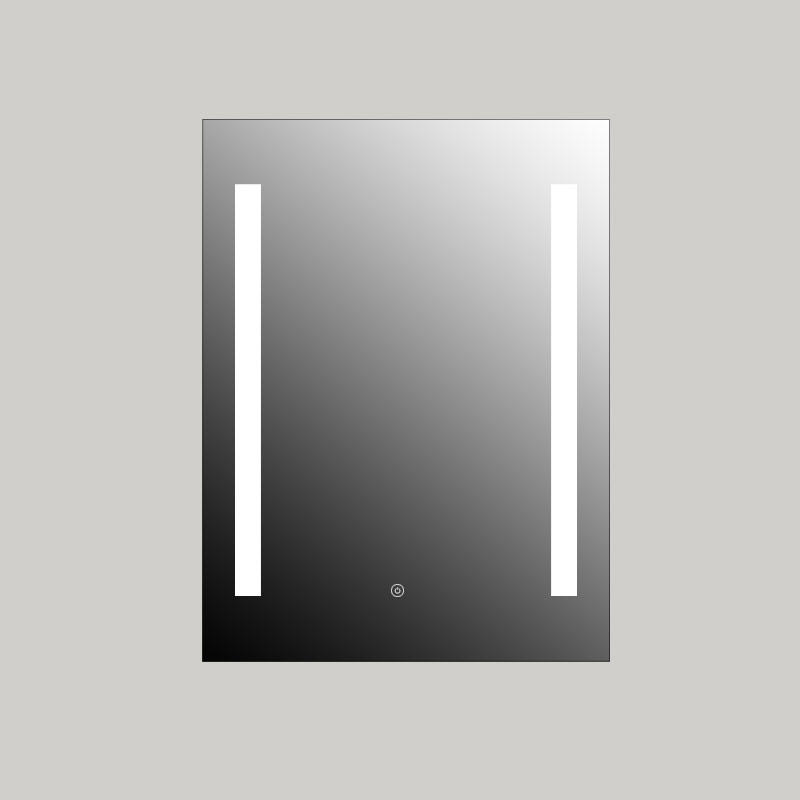

Rectangle LED Bathroom Mirror with Dimmer C015

-

Rectangle Acrylic Backlit LED Bathroom Mirror with Dimmer Color Temperature Adjsuting C077

-

Rectangle Wall Mirror LED Bathroom Backlit Mirror with Colok Defogger C078

-

Rectangle 3000K Wall Mounted LED Bathroom Mirror with Magnify Mirror for Make Up C094

-

Irregular Shape PS Frame Bathroom Mirror

-

.jpg?imageView2/2/format/jp2)

Rectangular PS Framed Bathroom Mirror

-

-1.jpg?imageView2/2/format/jp2)

Oval PS Frame Wall Mirror

-

Round Light PS Framed Wall Mirror

-

Arch Shape Stainless Steel Framed Wall Mirror SSAR-01

English

English عربى

عربى Español

Español