Professional glass and mirror processing enterprise with 15 years’ experience and expertise. Integration of design, production, marketing, customer service.

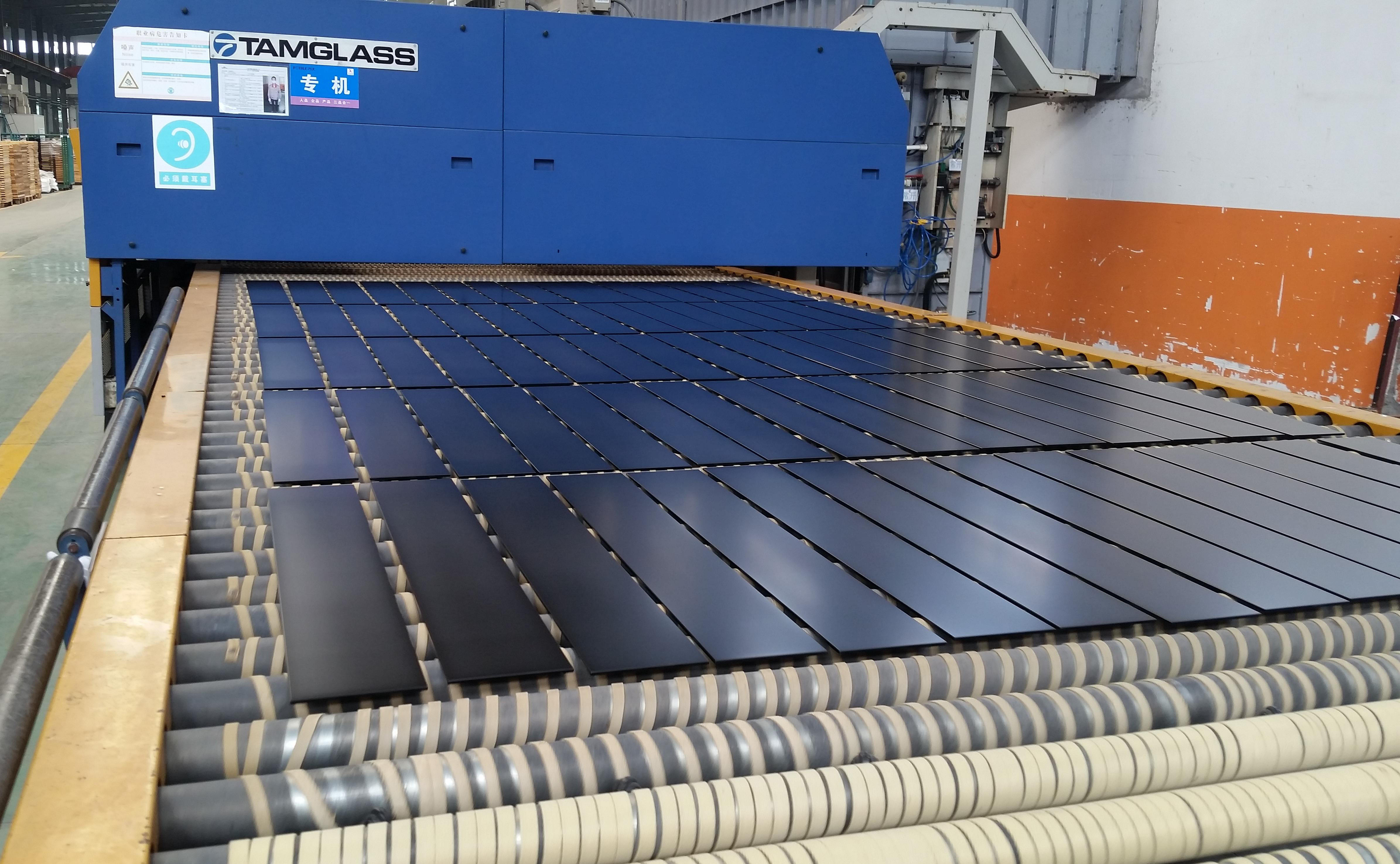

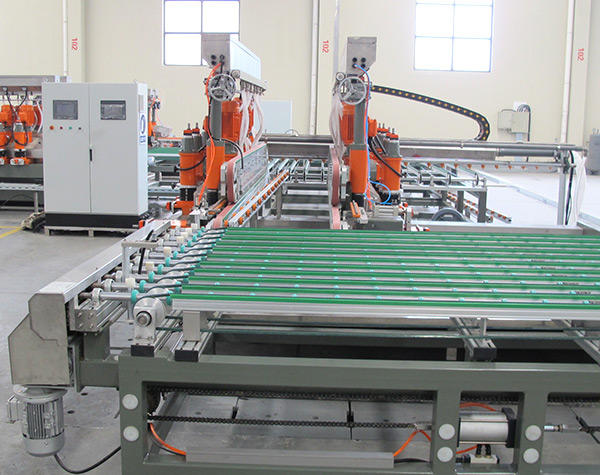

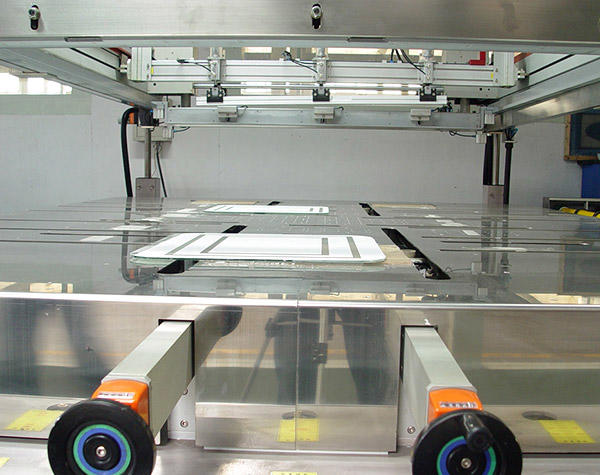

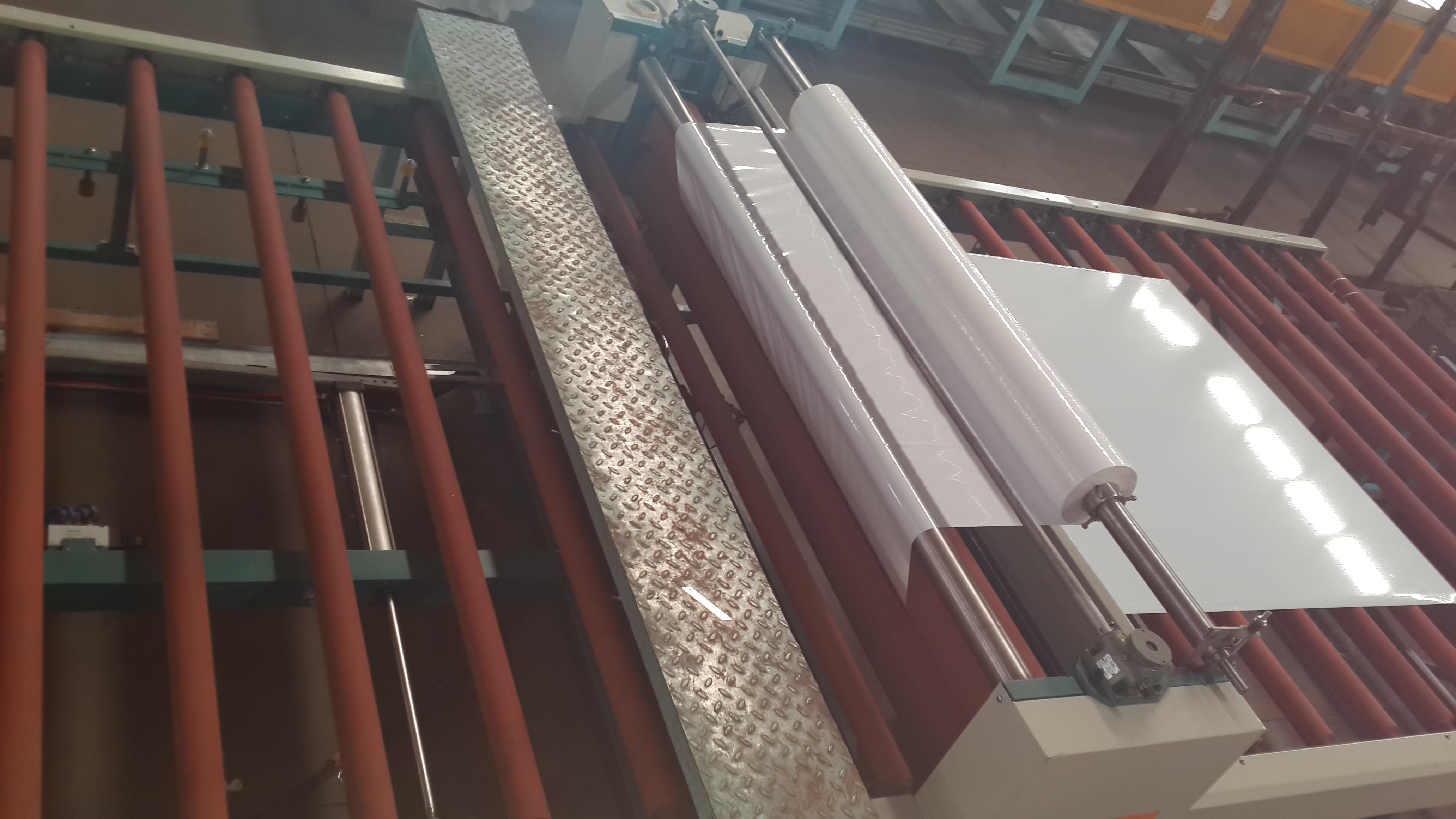

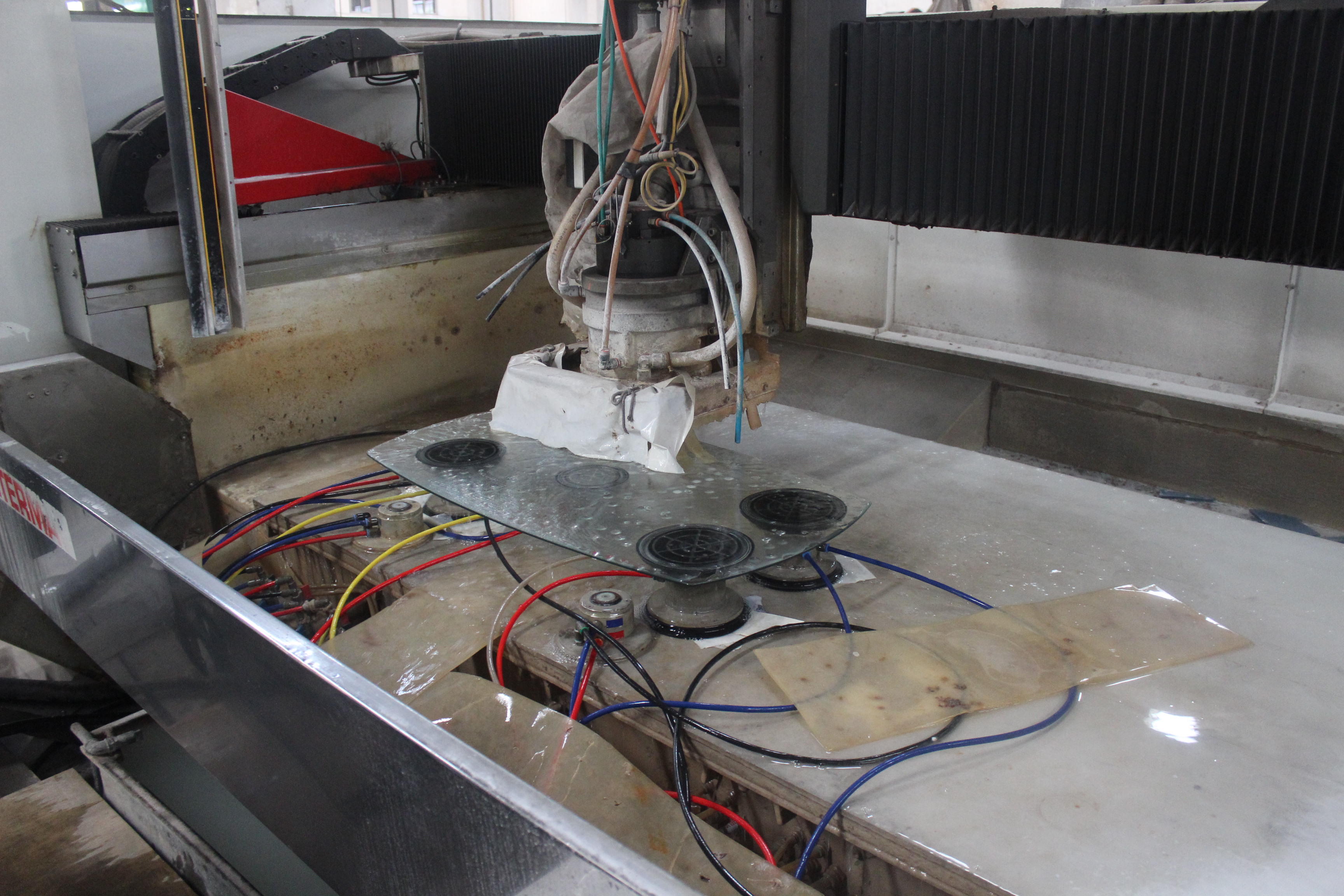

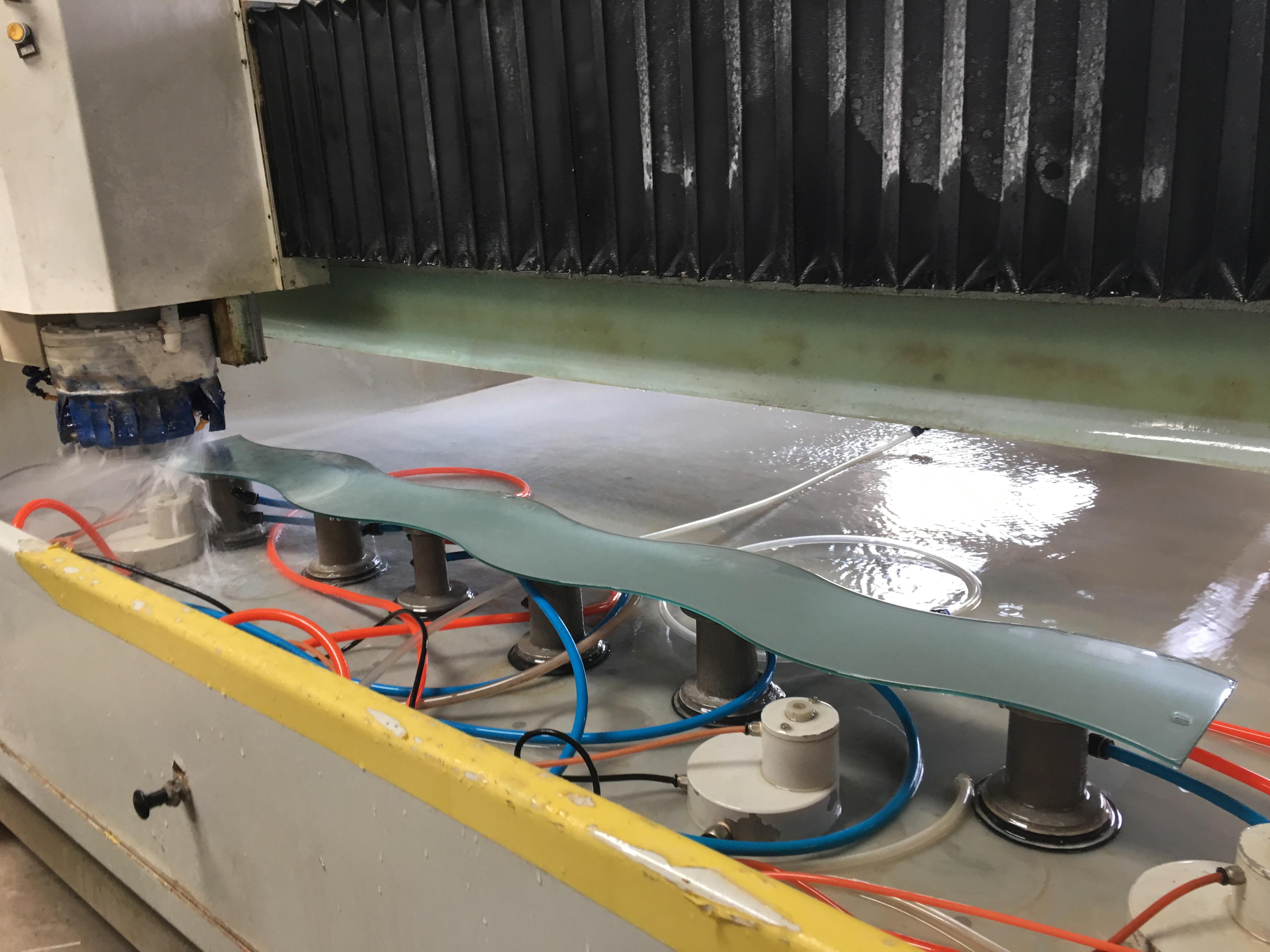

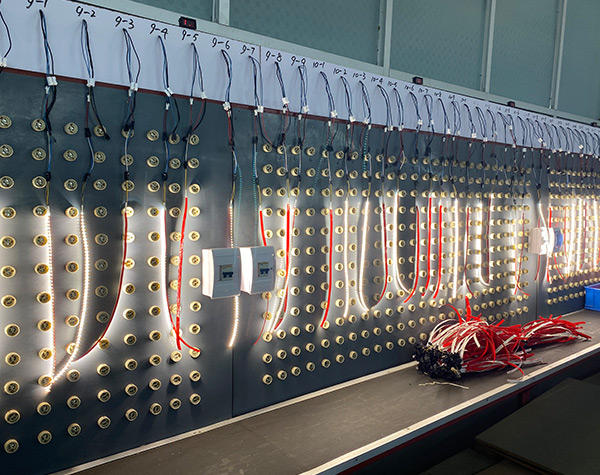

We use the latest technology.Computerized glass cutters, automatic glass edge grinding machine, as well as laser-engraving and continuous tempering furnace.

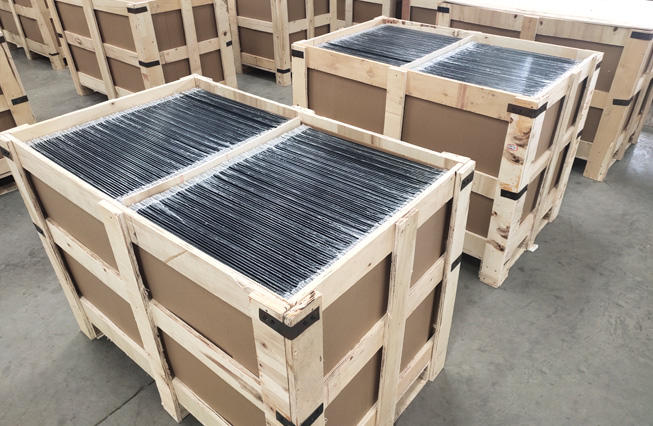

Full ranges of glass and mirror products to meet your one-stop purchasing requirements.

English

English عربى

عربى Español

Español