When it comes to the world of glass installation, the process for vacuum glass significantly differs from that of regular glass. As a supplier of vacuum glass, I've witnessed firsthand the nuances that set these two types of glass apart during installation. In this blog, I'll delve into the key differences, highlighting why understanding these distinctions is crucial for a successful installation.

Structural Characteristics and Their Impact on Installation

Regular glass is typically a single - pane or double - pane structure. Single - pane glass is just a simple sheet of glass, while double - pane glass consists of two glass panes separated by a small air gap. The installation of regular glass is relatively straightforward due to its simple structure. For single - pane glass, it can be easily cut to size, and then installed using basic glazing techniques. Double - pane glass, although a bit more complex, still follows a well - established process. It can be placed in window frames with minimal additional equipment, and the air gap provides a certain level of insulation.

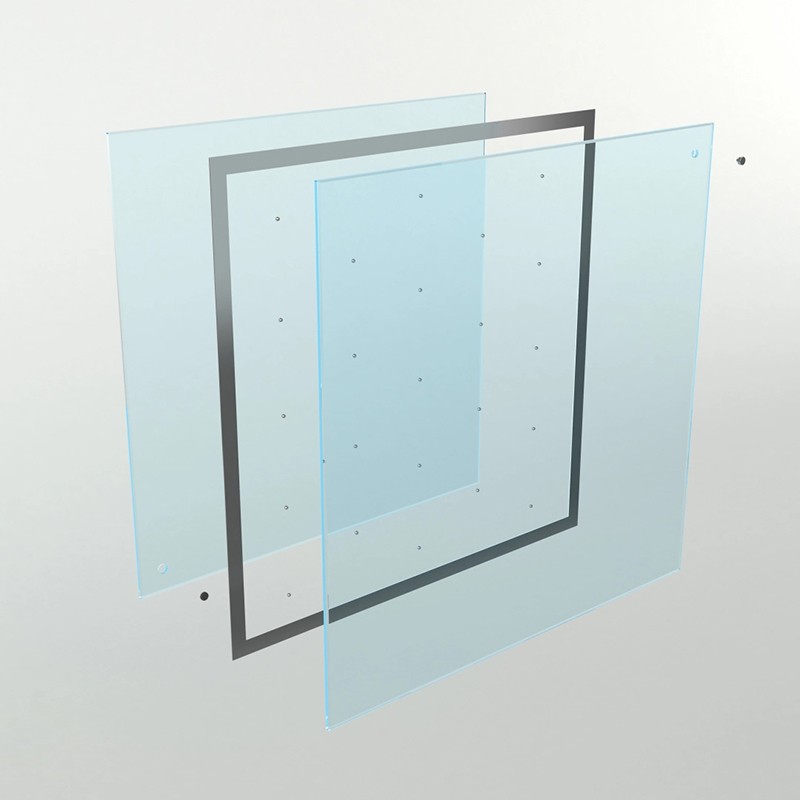

On the other hand, Vacuum Insulated Glass (VIG) has a unique structure. It consists of two glass panes separated by a tiny vacuum layer, usually only a fraction of a millimeter thick. The vacuum is created by removing almost all the air between the two panes, which requires a high - precision manufacturing process. This structure makes vacuum glass much more energy - efficient than regular glass, but it also means that the installation process must be more meticulous.

Precautions During Handling

Regular glass is relatively sturdy and can withstand a certain amount of rough handling during transportation and installation. Of course, it still needs to be handled with care to avoid breakage, but minor bumps and vibrations are less likely to cause significant damage. Workers can carry regular glass panes by hand, using simple lifting equipment if necessary.

In contrast, vacuum glass is extremely sensitive to external pressure and impact. The vacuum layer inside the glass is maintained by a delicate balance, and any damage to the edge seal or the glass surface can lead to the loss of the vacuum, reducing its insulation performance. When handling vacuum glass, special care must be taken. We recommend using dedicated lifting devices with soft pads to avoid scratching or cracking the glass. The glass should be transported in a vertical position to prevent uneven stress distribution.

Installation Tools and Equipment

For regular glass installation, basic tools such as glass cutters, glazing knives, and sealant guns are commonly used. These tools are relatively inexpensive and easy to operate. The installation process mainly involves cutting the glass to the appropriate size, fitting it into the window frame, and sealing it with putty or sealant.

When installing Vacuum Insulated Glazing, more specialized tools are required. A vacuum pump may be needed to test the integrity of the vacuum in the glass before installation. Additionally, precision measuring tools are essential to ensure that the glass fits perfectly into the window frame. Any misalignment can cause stress on the glass, potentially leading to damage. Specialized sealants are also used to ensure an air - tight seal around the edges of the glass, which is crucial for maintaining the vacuum.

Installation Environment Requirements

Regular glass can be installed in a wide range of environments. It can be installed in both indoor and outdoor settings, and the temperature and humidity conditions do not have a significant impact on the installation process. As long as the installation area is clean and free of debris, the installation can proceed smoothly.

Vacuum glass, however, requires a more controlled installation environment. The installation area should be clean and dust - free to prevent particles from getting between the glass panes and damaging the vacuum. The temperature and humidity should also be within a certain range. High humidity can cause condensation on the glass surface, which may affect the sealant's performance. In addition, the installation should be carried out in a relatively stable environment to avoid sudden temperature changes or vibrations.

Sealing and Insulation

In regular glass installation, the sealing is mainly to prevent water and air leakage around the edges of the glass. Common sealing materials include putty, silicone sealant, and weatherstripping. While these seals can provide a certain level of insulation, they are not as effective as the vacuum insulation in vacuum glass.

The sealing of Vacuum Glazing is a critical step in the installation process. The edge seal must be air - tight to maintain the vacuum between the two glass panes. Specialized edge sealing materials are used, which are designed to withstand long - term exposure to the environment without losing their sealing properties. The insulation performance of vacuum glass largely depends on the quality of the edge seal. A well - sealed vacuum glass can significantly reduce heat transfer, making buildings more energy - efficient.

Cost and Time Considerations

The installation of regular glass is generally less expensive and quicker. The cost of tools and materials is relatively low, and the installation process is well - understood by most glaziers. This makes regular glass a popular choice for budget - conscious projects or those with tight deadlines.

Installing vacuum glass, on the other hand, is more costly and time - consuming. The high - precision manufacturing process of vacuum glass makes it more expensive than regular glass. The specialized tools and equipment required for installation also add to the cost. Additionally, the more meticulous installation process means that it takes longer to complete the installation. However, the long - term energy savings and improved comfort provided by vacuum glass often justify the higher upfront cost.

Why Choose Our Vacuum Glass

As a vacuum glass supplier, we are committed to providing high - quality products and professional installation guidance. Our vacuum glass is manufactured using the latest technology, ensuring a perfect vacuum layer and excellent insulation performance. We offer comprehensive support to our customers, from product selection to installation. Our team of experts can provide on - site training to ensure that the installation is carried out correctly.

If you're considering upgrading your windows or starting a new construction project, we encourage you to explore the benefits of vacuum glass. The superior energy efficiency and comfort it provides make it a worthwhile investment. Contact us today to discuss your specific needs and start the procurement process. We look forward to working with you to create a more sustainable and comfortable living or working environment.

References

- "Glass Installation Handbook", Industry Publication

- "Energy - Efficient Glazing Technologies", Academic Journal

- "Advances in Vacuum Glass Manufacturing and Installation", Research Report