Classification of glass materials

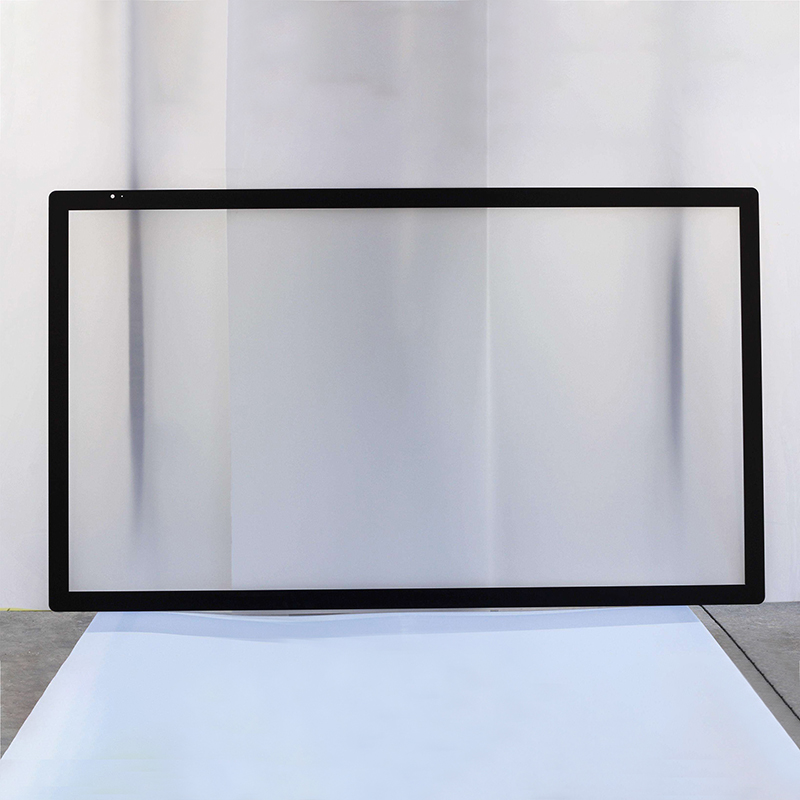

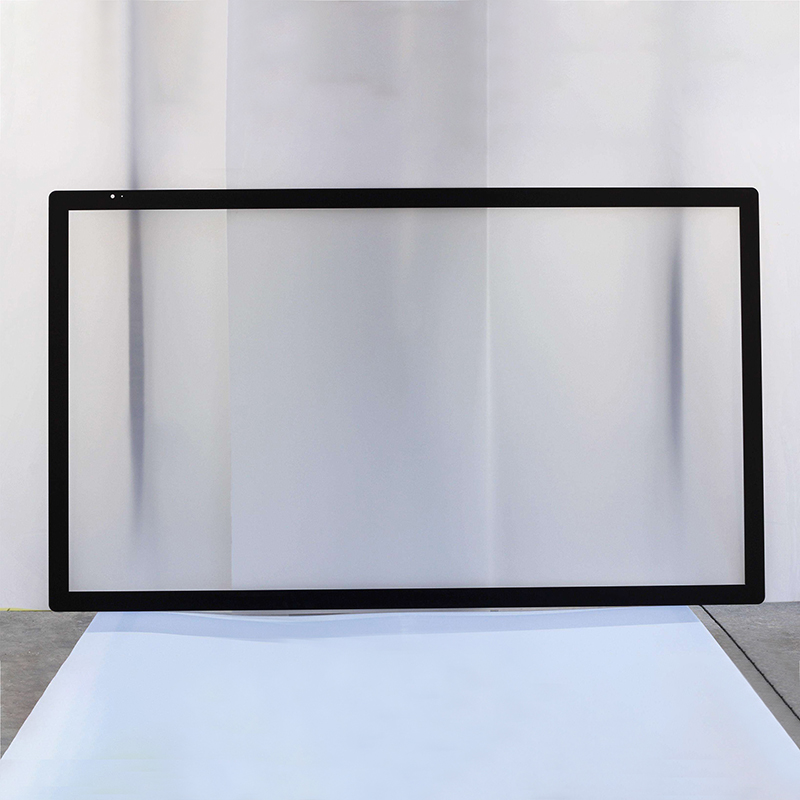

The first category is glass plate, which is mainly used for the parts that need lighting in decoration. There are flat glass, patterned glass, frosted glass, coated glass, engraved glass, tempered glass and other varieties, which can be selected according to the requirements of different parts and different decorative effects. .

The other type is glass bricks, which are mainly used for glass partitions, glass walls and other projects, mainly hollow glass bricks. It can be divided into single-cavity and double-cavity, and has various specifications such as square brick and rectangular brick, and its surface shape is also very rich, which can be selected and used according to decoration needs.

Quality identification of glass materials

1. Inspection of glass sheets. The appearance quality is mainly to check the flatness and observe whether there are quality defects such as bubbles, inclusions, scratches, lines and fog spots. Glass with such defects will deform during use, which will reduce the transparency and mechanical strength of the glass. And the thermal stability of glass, it is not suitable for engineering. Since glass is a transparent object, the quality can be basically identified by visual inspection during selection.

2. Inspection of glass processed products. In addition to testing according to the requirements of flat glass, it should also check its processing quality, check whether the specifications and dimensions are standard, whether the processing accuracy and pattern clarity meet the requirements, and the edges are not allowed to have defects.

The appearance quality of hollow glass bricks is not allowed to have cracks, no opaque unmelted material is allowed in the glass blank, and poor welding and bonding between the two glass bodies are not allowed. Visual inspection of the brick body should not have ripples, bubbles and layered streaks caused by inhomogeneity in the glass body. The inner concave of the large outer surface of the glass brick should be less than 1 mm, and the outer convex should be less than 2 mm.

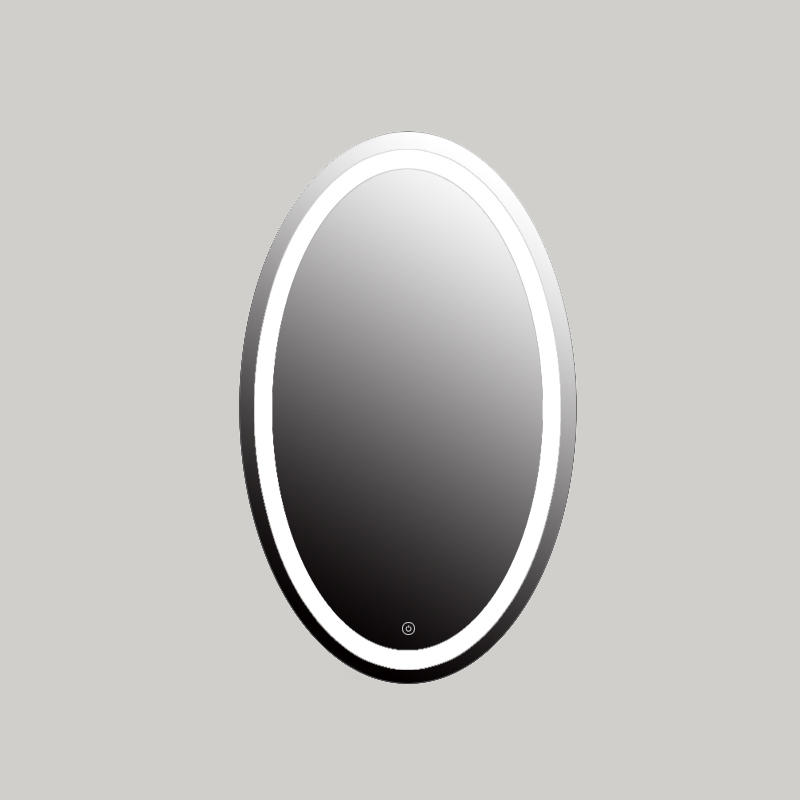

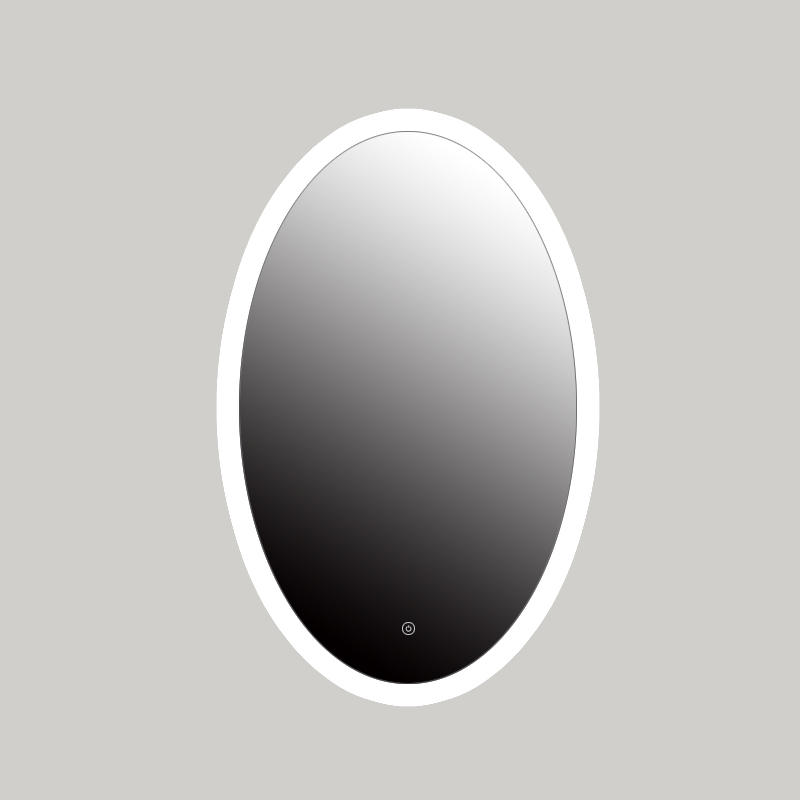

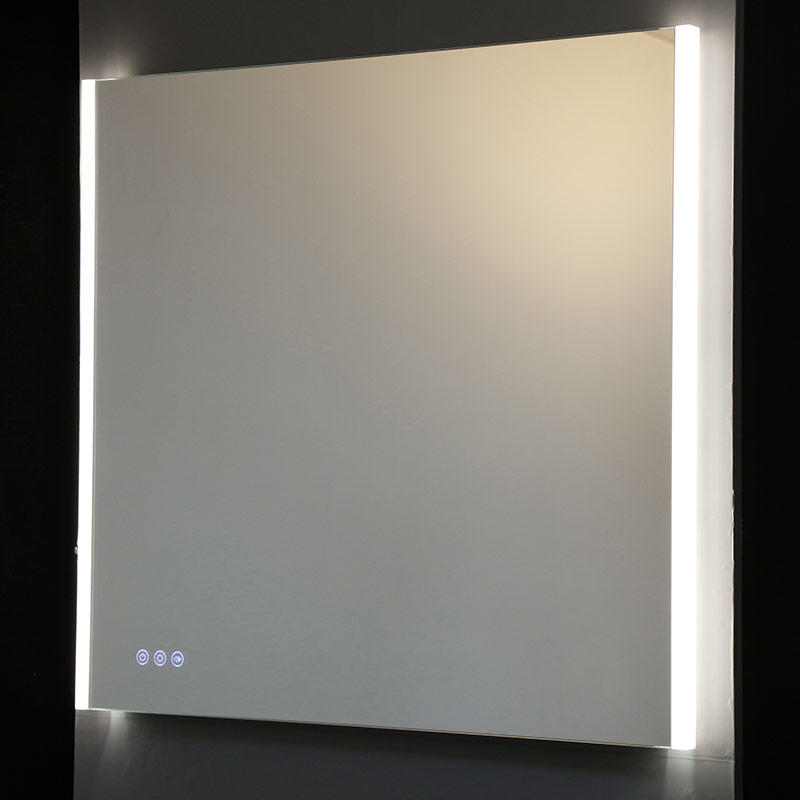

Hangzhou Jinghu Glass Co., Ltd. is one of the most significant glass and mirror manufacturer in China with more than 15 years of experience with a factory covering a space of 12,000sqm. Since its founding, Jinghu glass has been constantly upgrading its factories to be a comprehensive factory that meets world-class standards in producing processed glass and mirror, finished mirror integrating design, research, production, marketing and after-sales services. As OEM Glass Furniture Manufacturers and Custom Glass Furniture Factory, We strictly control the quality in production and after production, to keep the good quality before send to customers. Full ranges of glass and mirror products to meet your one-stop purchasing requirements.

Hangzhou Jinghu Glass Co., Ltd. is one of the most significant glass and mirror manufacturer in China with more than 15 years of experience with a factory covering a space of 12,000sqm. Since its founding, Jinghu glass has been constantly upgrading its factories to be a comprehensive factory that meets world-class standards in producing processed glass and mirror, finished mirror integrating design, research, production, marketing and after-sales services. As OEM Glass Furniture Manufacturers and Custom Glass Furniture Factory, We strictly control the quality in production and after production, to keep the good quality before send to customers. Full ranges of glass and mirror products to meet your one-stop purchasing requirements.

English

English عربى

عربى Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)